Understanding how a batch freezer works is essential for producers

who want precise control over texture, overrun, and consistency—especially in ice cream, gelato, and other frozen desserts.

Unlike continuous systems, batch freezing is a hands-on, dynamic process where cooling, agitation, and air incorporation happen simultaneously and can be adjusted from batch to batch.

This step-by-step explanation breaks down how a batch freezer works and why the process remains relevant for premium and small-scale production.

A batch freezer is a freezing machine that processes a fixed amount of liquid mix at a time. Each batch is frozen, discharged, and then the machine is refilled for the next cycle.

If you’re new to the concept, start with a full overview here:

What Is a Batch Freezer? Definition, Process & Applications

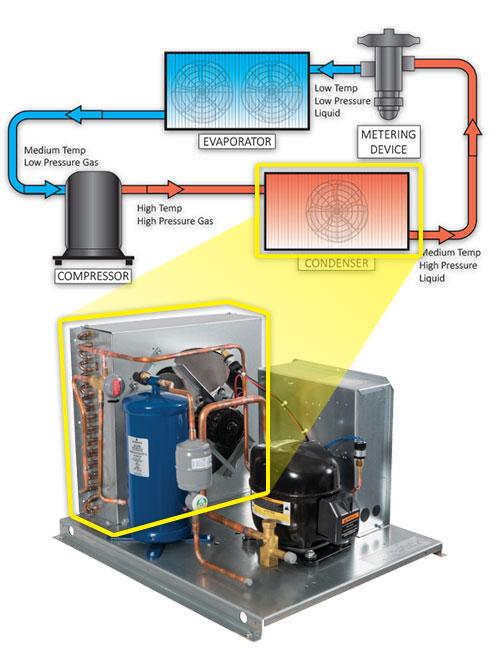

Step 1: Heat Removal Through the Freezing Cylinder

The batch freezing process begins when liquid mix is poured into the freezing cylinder.

-

The cylinder wall is cooled by a refrigeration system

-

Heat transfers from the mix to the cold surface

-

The temperature of the mix drops rapidly

This direct contact between the mix and the refrigerated surface is what initiates freezing.

Step 2: Agitation and Ice Crystal Formation

As the mix cools, ice crystals begin to form on the inner wall of the cylinder.

A rotating dasher:

-

Scrapes ice off the cylinder wall

-

Keeps crystals suspended in the mix

-

Prevents large ice crystals from growing

This agitation is critical. Smaller, evenly distributed ice crystals result in a smoother texture and a higher-quality frozen product.

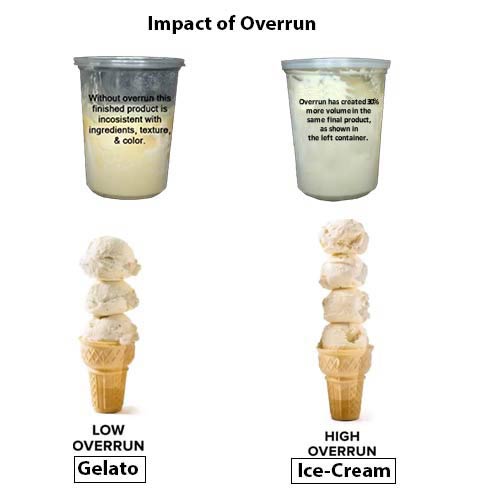

Step 3: Air Incorporation (Overrun Control)

While freezing and agitation continue, air is incorporated into the mix.

This process—known as overrun—directly affects:

-

Density

-

Mouthfeel

-

Yield

Because batch freezers operate one batch at a time, producers can:

-

Adjust overrun manually

-

Fine-tune texture for different recipes

-

Achieve distinct product styles (e.g., gelato vs ice cream)

This level of control is one of the key advantages of batch freezing.

Step 4: Monitoring Consistency and Structure

Unlike automated continuous systems, batch freezing relies on operator judgment.

Producers monitor:

-

Resistance on the dasher

-

Visual texture

-

Product temperature

Once the target consistency is reached, the freezing process is stopped immediately to preserve the desired structure.

Step 5: Product Discharge

The finished frozen product is discharged directly from the batch freezer.

Immediate discharge is important because:

-

Over-freezing can damage structure

-

Excessive ice growth reduces smoothness

-

Texture can degrade if the product remains in the cylinder too long

After discharge, the batch freezer is ready for the next cycle.

Why Batch Freezing Matters

Batch freezing remains widely used because it allows producers to:

-

Adjust texture on a per-batch basis

-

Experiment with new recipes and formulations

-

Maintain consistent quality in small or premium production

-

Retain hands-on control over the freezing process

For many producers, especially in artisan and specialty markets, this flexibility outweighs the efficiency of continuous freezing systems.

Batch Freezer vs Continuous Freezer: Where It Fits Best

Batch freezers are ideal when:

-

Product variety is high

-

Production volumes are moderate

-

Texture and recipe control are priorities

To understand how batch freezers compare with high-capacity systems, see:

What Is the Difference Between a Batch Freezer and a Continuous Freezer?

Final Thoughts

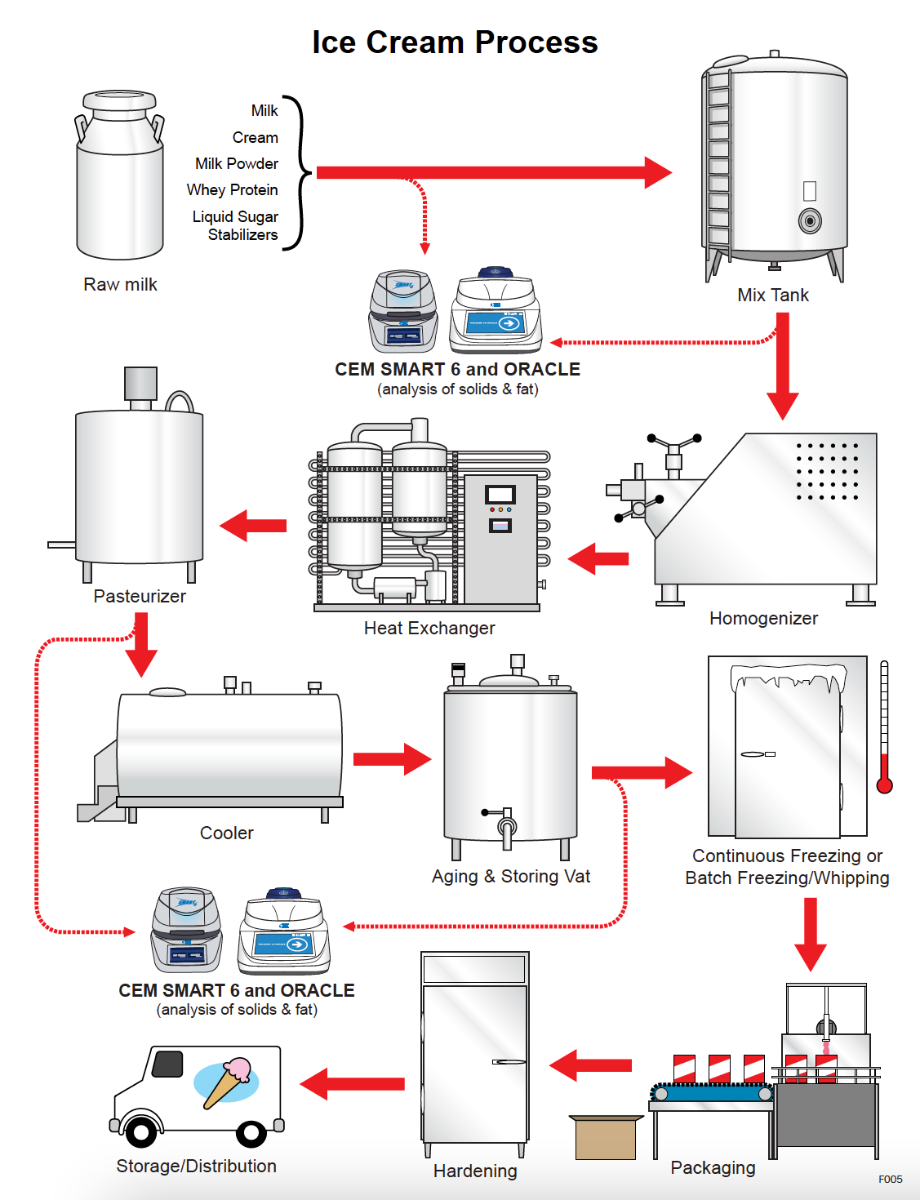

A batch freezer does more than simply freeze a liquid mix. It shapes structure, texture, and eating experience through controlled cooling, agitation, and air incorporation.

While continuous freezers dominate large-scale production, batch freezing remains the foundation for producers who value flexibility, experimentation, and premium frozen dessert quality.